When you’re shopping for a door, it’s easy to get bogged down in considerations about how the door looks. If you’re shopping online, then this is understandable, as you’ll be gleaning your first impressions from an intangible image of the product, rather than from touching, pushing and pulling it.

But perhaps just as important as the way a door looks on the outside is the way it’s built on the inside. By making use of different manufacturing methods, and different sorts of wood, it’s possible to create doors that feel differently when we open and close them, which are able to preserve heat more effectively, and which uses far less timber – and thereby places far less strain on the environment.

Solid Wood, Veneer and Engineered Wood: What Are They?

There are two main methods of building a door (or any piece of wooden furniture). One can either use solid wood, or a ‘veneered’ piece.

What are Solid Wood Doors? The entire door is built from a single species, solid piece of wood, or pieces of wood that are glued together. Though many separate pieces of wood might go into making a solid-wood door, each of them will be continuous from one side of the door to the other.

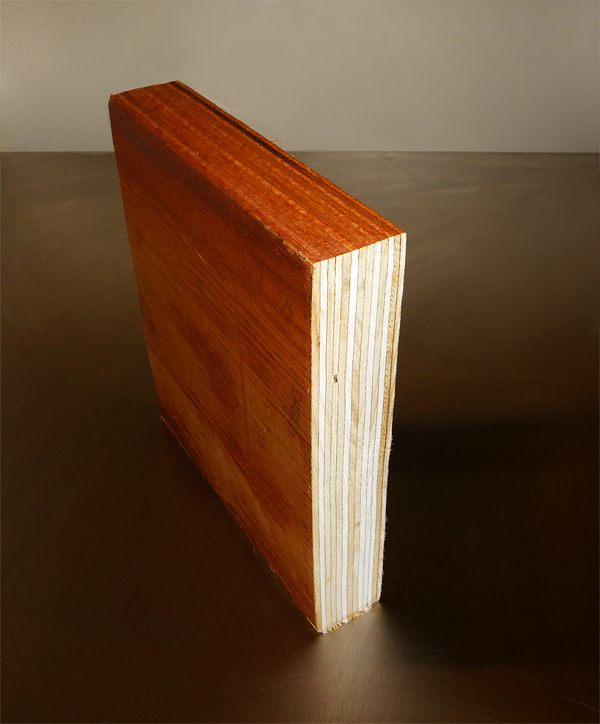

What are Engineered Doors? They pack the body of the door with less expensive, internal pieces of wood, and cover the exterior with an outer layer of more expensive wood. This outer layer is known as the veneer, and it’s this layer that gives an engineered piece of wood the appearance of a hardwood that would be far more expensive were the entire door constructed from it.

When we think of engineered wood, we might think of the chipboard we might find in an inexpensive piece of flat-pack furniture – tiny fragments of wood that have been blasted from the small, fiddly parts of a tree and then glued back together. There is some truth to this idea – some veneered doors are indeed made in this way, with others manufactured using finger jointed laminated timbers or even MDF, all of which will have a “lipping” manufactured from the same species of material as the veneer. This lipping allows the door to be trimmed and a 0.6-0.9mm thick veneer on the face of the door will give it the look of solid timber doors. These engineered doors are less expensive to manufacture, and also have the added benefit that they won’t bow or twist.

Even the more expensive veneers will still make the same economy – placing the most expensive and attractive wood on the outside of the door, and thereby ensuring that it looks as good as can be for minimal cost.

But engineered doors aren’t simply a cost-saving exercise, and contrary to popular belief, nor are they always packed with cheaper materials. So what are engineered doors made of? Engineered doors are manufactured from chipboard, MDF, or laminated tiny pieces of timber. It depends on the factory as each factory makes them differently.

So which ones should you buy? Solid wood, engineered wood, or veneer doors?

We might assume that a solid wood door is inherently better than an engineered one. But there are some respects in which the latter performs just as well as the former. Indeed, there are some respects in which it does even better. Let’s examine some of the key areas of difference.

Cost

In most cases, we find that a solid wood door costs more than an engineered one. Since there’s so much more engineering involved in an engineered door, one might assume the opposite. So why is solid wood so expensive when compared to its rival? The answer lies in the timber being used.

The best solid wood doors are made entirely from expensive hardwood, like oak. Since a door can be several centimetres thick, the amount of oak required to create it is considerable. Compare this to an engineered door, where only the outer layer, just a few millimetres thick, is made from solid oak, while the inner parts are made from far less expensive timber, and it’s easy to see how a solid wood door might command a far higher price than an engineered one.

We should also factor in the fact that the less expensive timber on the inside is often drawn from parts of a tree that might not otherwise even be used – like the smaller branches and knots. An engineered door will find a use for these parts, and can therefore be considered not only the cheaper option – but the more environmentally friendly.

Browse our solid oak bifold patio door range and open up your living space. Stunning, fully-finished bifold doors at fantastic prices. Shop now!

Performance

After we’ve considered the price of the door, we should consider what we’re getting for our money. Some inexpensive doors will tend to display evidence of cut corners within a few months of their lifespan. For example, if a veneer has been applied badly to a door, then bubbles may have formed underneath it. These bubbles can be made either from air or glue – and will be either collapsible or solid depending on which material is trapped. In either instance, you’ll have an unsightly blemish on your door – and one whose removal is remarkably difficult, and involves the use of an iron or a razor-blade on your door.

Thankfully, not all veneered doors suffer from such problems – the best, like the ones you’ll find on this site, will have been painstaking put together, and look just as good as their solid-wood counterparts.

They’re also resistant to warping – which is among the most glaring weaknesses of the solid-wood door. Warping occurs when a solid piece of wood responds to changes in the surrounding climate. Tiny changes in temperature and airborne moisture can cause the wood to expand and contract, which over time can change the shape of the door. The result is a door that catches and sticks, and whose surface is prone to cracking. By applying a coat of wax or polish to your door, you’ll be able to offer it protection against changes in moisture, which in turn will help to guard against unwanted warping.

Since engineered doors are built from a greater variety of different timbers, manufacturers are able to achieve far more consistency. While solid-wood doors might look and feel considerably different from one another, engineered wood doors and veneered doors tend to look and feel almost exactly alike.

Energy Efficiency

The energy efficiency of a door is crucial – particularly if the door is an external one, tasked with keeping cold air on the outside of a house and warm air on the inside. When considering energy efficiency, we should be concerned with two different threats – the convection of heat from one side of the door to the other, and the danger of cold draughts passing directly through the cracks between the sides of the door and the surrounding frame.

When it comes to excluding draughts, warping is a problem. Even a difference of a single millimetre on the sides of a door can allow an enormous amount of cold air into a house over the course of a year. That’s why the warp-resistant nature of engineered oak doors can be handy. Since the materials which make up the core are all running in different directions, the stress of warping is distributed evenly through those layers. Effectively, the different planks of wood will cancel out each other’s warping, and the result will be a door whose shape is consistent. By the same token, a modern engineered core will have better thermal performance than a solid piece of wood, making it a better choice for external doors.

Adjustment

Thus far, we’ve heard a great deal about the advantages of an engineered door. But there’s one drawback that we often encounter when first installing a door, or later when we come to treat it, or attempt to remove chips. Since the outer veneer of an engineered door is so thin, we’re only able to smooth it so much through sanding before we break through into the inner core of the door. Obviously, doing this would have a horrendous impact on the look of the door itself.

When we first install a door, we’re often required to make adjustments to the side in order for it to make the best possible fit into the frame. Consequently, the veneer needs to be thicker on the sides of the door than it is on the faces.

This layer of high-quality wood on the side of the door is known as the lipping. It can be anywhere from a few millimetres wide to a few centimetres, depending on the size of the door. Thanks the lipping, we’ve leeway to make slight adjustments to the side of the door if it’s required.

A solid-wood door requires no lipping, as the material is the same throughout the door. It will therefore be just as adjustable – on both the sides and face of the door, and you won’t need to worry about considerations like the depth of lipping before breaking out a belt-sander.

In conclusion

Solid-wood and veneered or engineered doors each have their advantages, but when comparing the two it’s worth also considering that there are many different sorts of veneered doors, each with their own merits. Solid-wood doors tend to be more expensive, thanks to the cost of the timber used to produce them – and they’re inherently stronger and more solid. But an engineered door might hold its shape better, and offer better insulation over time. Our internal doors are all engineered, including our interior French doors. If you’re unsure which sort of door might make the better fit for your home, then why not get in touch with our team of advisors? They’ll be able to explain the various merits of each item in our catalogue – external doors or internal doors – and address any queries you might have about the doors we sell.